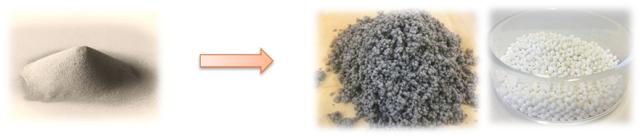

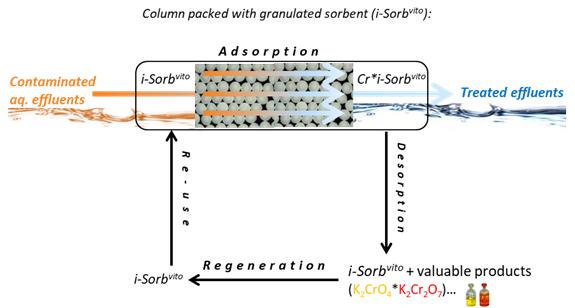

The developed sorbent materials are shaped into granulates enabling their application in column set-ups with high hydraulic conductivity, easily replaceable and safe. Granular sorbents will be produced at VITO and sent for application testing at the Indian demonstration site. The composition of the designed sorbents will be adapted to the specific conditions of the Indian test-cases (considering relevant concentrations and possible competitive ions).

However, the high sorption capacity, low cost production and regeneration abilities will be present as well. In such a configuration the proposed technology follows the removal-recovery-reuse approach in which the wastewater purification (by sorption onto the granulated material), metal (Cr) and/or nutrient (P) recovery or removal (by desorption) is concomitant with a sorbent regeneration step allowing its reuse in a new wastewater purification step and the recovery of the valuable metals and nutrients.

Working principles

Requirements for a good sorption material:

- High loading capacity and (controlled) selectivity (material property) and regenerability

- Good permeability (shape property)

- applicable in column set-ups

- improved mass transfer

- low-pressure drops

Test results and evaluation

Wastewater treatment and reuse

Lab-scale experiments focused on structured sorbents for wastewater treatment, with Sorbent 1, composed of 80% LDO and 20% bentonite, being identified as the optimal composition for adsorbing Cr3+ and Cr6+. Batch tests revealed that higher solid-to-liquid (S/L) ratios improved Cr recovery efficiency, achieving removal efficiencies of 93-96% with a 2.5 g/100mL influent S/L ratio. An optimal desorption and regeneration solution using 2M NaCl with a neutral pH was found. Afterwards, the kinetic and isotherms for Cr sorption on self-structured adsorbents were studied, and it was determined that higher S/L ratios enhanced Cr recovery efficiency. Finally, columns designed based on feasibility tests and modelling ran for approximately 50 days. Regeneration of columns was achieved with a 2M NaCl solution at a neutral

pH, but pH adjustment was required for the highly basic effluent before further use or disposal. As at this stage only limited experiments were performed under flow conditions, future work should include

the optimization of operation parameters under flow conditions, validation of the regeneration procedure under dynamic conditions (to enable the multicycle use) and the investigation on the use/regeneration/disposal of the exhausted structured adsorbents.

Finaly, as this technology was demonstrated for various Cr concentrations, namely at small scale for effluents containing high Cr concentrations and at larger scale for low Cr concentrations, it will be important to test it under various Cr containing wastewater sources and investigate its applicability for wastewater treatments in different industrial sectors.

For more details, consult the deliverable report*:

Laboratory test reports and fact sheets on water treatment technology and reuse

* The deliverable report is still under review and has not yet been approved by the European Commission. The final approved version will be uploaded as soon as possible.

Resource Recovery

The study involved evaluating the performance of sorbent materials under equilibrium conditions, followed by the selection of the sorbent composition and optimization of Cr recovery and regeneration. Subsequent batch tests at VITO demonstrated exceptional adsorption and regeneration efficiencies, consistently reaching 95- 100% over five cycles. Thus, the optimal sorbent composition (Sorbent 1 with 80% LDO and 20% Bentonite) was defined for the recovery of Cr, and a 2M NaCl solution with neutral pH was identify for optimal regeneration. Additionally, Cr sorption tests at IIT Kanpur, which included investigations of isotherms, kinetics, and the influence of the solid-to-liquid (S/L) ratio, provided valuable kinetic parameters for column modelling and design. Simulation results suggested that the columns

should be operated at hydraulic loading rates of 0.5, 1, and 1.5 m3 /(m2 .d), with an influent Cr(VI) concentration of 1 mg/L and a minimum flow rate of 2 mL/min.

Lab columns operated at Kanpur for over 20 days did not reach the breakthrough of Cr sorption. This suggests the long-term effectiveness of the columns, with Cr concentrations consistently below the maximum accepted limits (50 ppb). Finally, a column with a 5 cm diameter and a 75 cm bed depth was able to treat around 165 L of wastewater before reaching Cr concentrations exceeding 50 ppb, with an operational duration of about 42 days. Similarly, a column with a 6 cm diameter and the same bed depth could treat approximately 270 L of wastewater before surpassing the 50 ppb Cr concentration limit, with an operational duration of roughly 55 days. As at this stage only limited experiments were performed under flow conditions, future work should include the optimization of operation parameters under flow conditions, validation of the regeneration procedure under dynamic conditions (to enable the multicycle use) and the investigation on the use/regeneration/disposal of the exhausted structured adsorbents. Finally, as this technology was

demonstrated for various Cr concentrations, namely at small scale for effluents containing high Cr concentrations and at larger scale for low Cr concentrations, it will be important to test it under various Cr containing wastewater sources and investigate its applicability for wastewater treatments in different industrial sectors.

For more details, consult the Deliverable Report*:

* The deliverable report is still under review and has not yet been approved by the European Commission. The final approved version will be uploaded as soon as possible.

Removal Efficiency

Results from previous projects

Horizon 2020 project CHROMIC (2016-ongoing)

This project conducted lab tests for selective recovery of chromates and vanadates from hydrometallurgical streams. The focus of this project is on selective adsorption and regeneration of sorbents.

The sorbents are synthetic clay-based powders and granulates.

Results: the sorbent sorption capacity is up to 60mg Cr6+/g. An increase of pH leads to reduced sorption capacity and the presence of carbonates may inhibit the sorption process. The optimization of sorbent regeneration is ongoing.

FWO Vlaanderen project 'Regenerable sorbent materials for aqueous waste streams' (2014-2017)

This project conducted lab tests for selective recovery of PO43- from aqueous stream with focus on selective adsorption and regeneration of sorbents. The sorbents are synthetic clay-based powders and granulates.

Results: sorbent sorption capacity up to 60mgPO43-/g, presence of carbonates may inhibit the sorption process, while P is adsorbed preferentially over Cl, NO32- or SO42-

Link to test reports: E.M. Seftel, B. Michielsen et al., Appl. Clay Sci. 165 (2018) 234-246

Interreg North Sea Region Nuredrain: Nutrients Removal and Recovery from Drainage Water (2017-2020)

This project performs lab tests for removal recovery of PO43- from aqueous streams with focus on adsorption of phosphate at different concentrations (0.5, 5, 25 ppm). The sorbents are: synthetic clay-based powders and granulates.

It involves one long-term column test of 200 days at low concentration (0.5 ppm).

The results: sorbent sorption capacity up to 15mgPO43-/g, fast kinetics (at influent concentration of 25mgPO43-/L).