Pavitra Ganga has developed a roadmap that seeks pathways towards a sustainable wastewater approach for the Kanpur Nagar area in Uttar Pradesh. The information also leads to a baseline scenario for the Jajmau sewage treatment plant, one of the two demosites of Pavitra Ganga.

The roadmap is the first deliverable of the Work Package Market uptake and business development and was developed by Aquafin, with the support of IIT Kanpur and VITO.

The overarching goal is to determine an ideal scenario with a 50 year horizon for future infrastructural investments in Kanpur Nagar. The roadmap carefully analyses the way towards a sustainable water reclamation service, incorporating the opportunities for recovering energy, materials and nutrients.

The plan takes into account, as much as possible, the principles of circular economics, where the positive potential of wastewater treatment plants is the central issue.

Analysis and screening

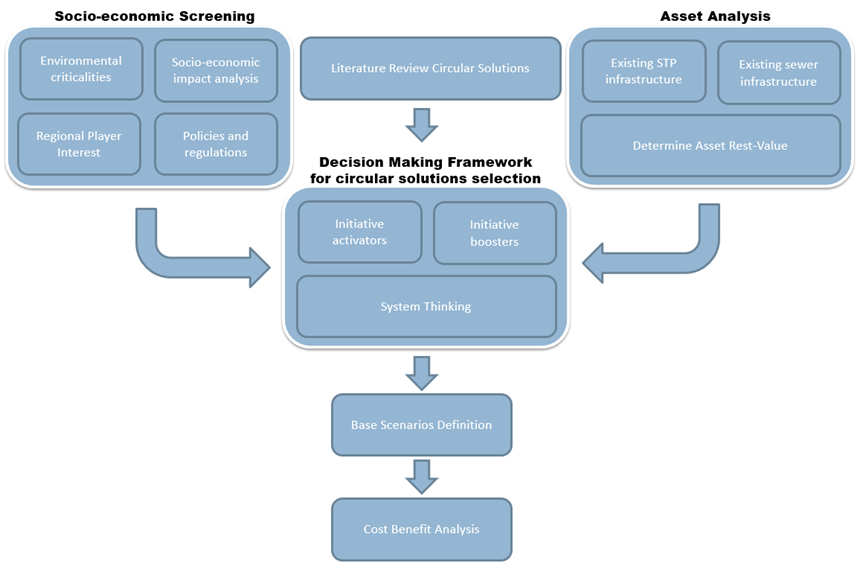

A multi-step process (scheme below) was deployed, starting with a screening in different sub-steps of the local conditions, the environmental pressures, the stakeholders’ interests and the specific local water resources.

In parallel, an evaluation of the actual assets’ situation was conducted in view of present and future investments. All this information has been used as input to a methodology to select and boost the most appropriate circular economy-based solutions.

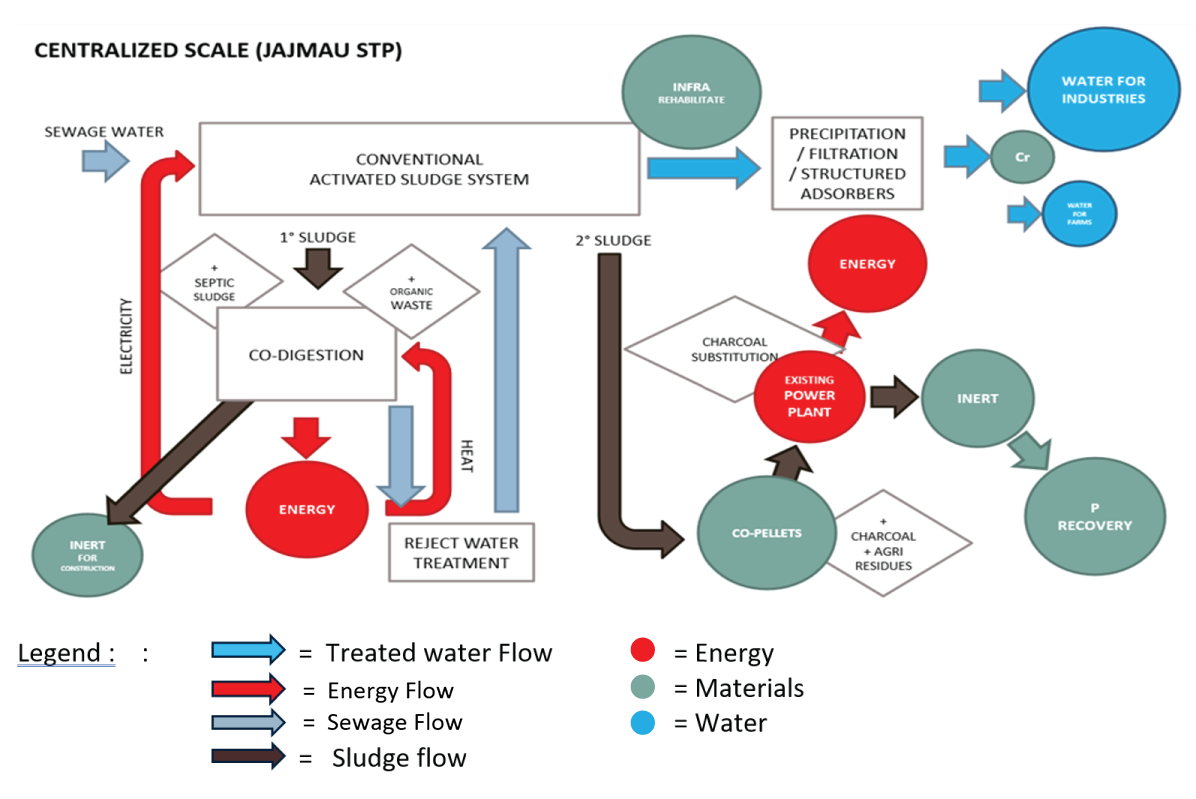

The overall information is processed into a centralized baseline scenario for the Jajmau STP (sewage treatment plant), that identifies four principle flows: Treated Water, Energy, Sewage and Sludge (illustrated in the scheme below).

Tanneries cluster

The nearby tanneries cluster has a negative impact on the possible choices of the different applications, especially when illegal wastewater discharges occur in the municipal sewage network. The toxicity of the emissions from the tanneries decrease the circular potential of specific solutions and this results in a lower environmental attractiveness of single standalone solutions.

The proposed base-line scenario foresees a conventional sewage treatment (STP) to produce effluent water, further treated to remove heavy metals and recover chromium solution.

The STP effluent water would be reusable for both industrial applications and agricultural applications, but with the priority given to industrial reuse-opportunities – as this sector has a higher capacity to contribute to cost recovery than the agricultural sector. However, there is also a strong argument to deliver safe irrigation water as a public good for local farmers, and also as an alternative to using freshwater surface or ground water supplies for irrigation.

Energy valorisation

The energy valorisation plays a crucial role in the circular approach. The possibility of mixing wastewater sludge with organic material (with high calorific potential) features in the roadmap wherever possible (both co-pelletization with farming residues, and primary sludge digestion with other organic sources).

Septic sludge and manure have been identified as ideal substrates for primary STP sludge co-digestion. While the primary STP sludge would be treated through digestion, the disposal and the valorisation of secondary STP sludge would depend mainly on sludge co-pelletization. Co-pelletized material could be sold to the domestic market or incinerated in biomass power plants as a substitute for coal.

Sludge incineration

It is important to realize that the energy valorisation of the wastewater sludge ultimately depends on the incineration of the secondary STP sludge. Moreover, sludge incineration is also a step for a number of powerful circular economy solutions. One of the solutions is the production of fertilizers, as the ashes resulting from the biomass power plants combustion can be further exploited in a high-rate phosphorous recovery process. Another solution is sludge inertisation for use in the construction sector or as a substitute for charcoal (mitigation against climate change).

Fertilizer production

Uttar Pradesh is an area with an important agricultural sector where the availability of fertilizers is of crucial importance. Considering that the production of phosphorous fertilizers from sludge ashes will not fully cover the need for other fertilizers, the additional production of compost would also offer circular success.

Most solutions explored in the roadmap aim to reduce health issues among farmers and livestock, but alsoreduce soil pollution. The fertilizer production and use would also reduce the cross-links between faecal waste streams and food-production pathways. For this reason, the production of organic fertilizers in the Kanpur Nagar region would be solely based on the compost production from food waste collection as a parallel activity to the roadmap proposed for the STP Jajmau.