From 6 until 9 June, the Pavitra Ganga project partners travelled to Antwerp (Belgium) for the 4th General Assembly. The Assembly’s programme was a nice balance between project and planning meetings for the final months of the project, relevant site visits and informal moments in a relaxed atmosphere.

Visit to VITO in Mol and Blue Foot Membranes in Lommel

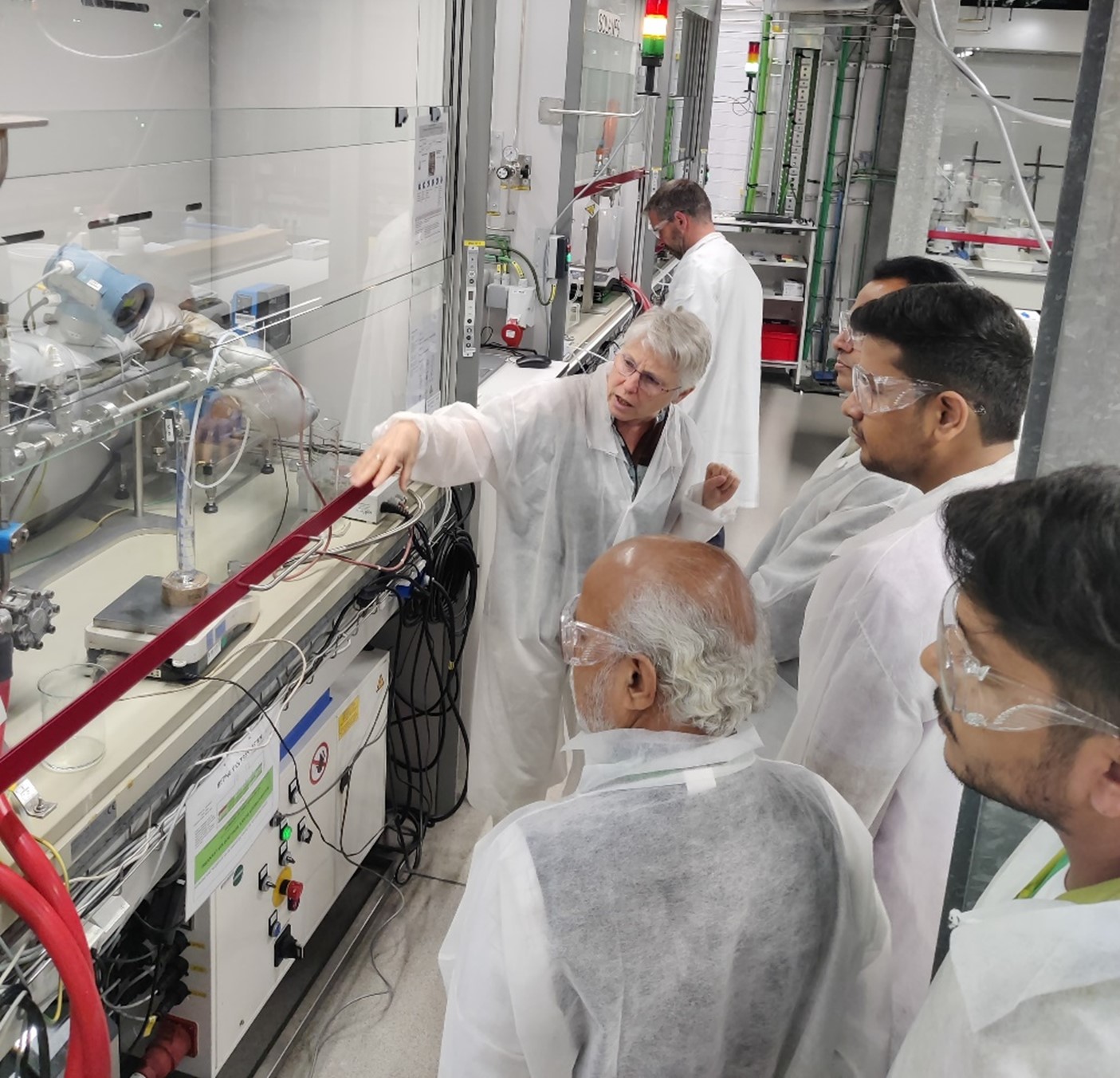

The first day of the Assembly was an optional study tour to the research facilities of VITO in Mol, which included participating in one of the VITO Lunch Talks, which happened to be about the membrane development activities at VITO, and then presentations about the WaterClimateHub and the Sustainable Chemistry Department. This was followed by a visit to the lab facilities of VITO with special attention to the structured adsorbents piloted within Pavitra Ganga, the membranes used for algae filtration and also new ceramic membranes being developed.

This was followed by a trip to the Blue Foot Membranes factory in Lommel. Blue Foot Membranes is the manufacturer of the IPC membranes that are used at Pavitra Ganga’s demonstration site in Kanpur.

The second day started with break out sessions for the work package partners to discuss the progress in small groups, while other project representatives were involved as presenters in the EU-India Water Projects webinar (partner event of the #EUGreenWeek).

The official General Assembly started in the afternoon of the second day, with all partners present. As the project is in its last year the focus of the presentations and discussions was on the key results and achievements of the project, outlining the strategies towards publications and finalizing the deliverables.

Aquafin visit

On the morning of the third day, the planning and remaining activities of the project were presented and discussed. In the afternoon, partners were invited for an optional study tour to the nearby Antwerp South wastewater treatment plant being operated Aquafin, where the visitors were given the chance to have an explanation of the nitrogen recovery technology pilot and the upgraded biogas production facility.