On 4 February 2021, the Water Research Institute of the National Research Council of Italy (CNR-IRSA), partner in the Pavitra Ganga project, published a scientific article in the International Journal of Environmental Research and Publich Health (MDPI) about the significance of the mesh pore sizing on the performance of the ‘Self Forming Dynamic Membrane BioReactor (SFD-MBR)’, a technology that is being piloted at Pavitra Ganga’s demo site in Kanpur, India.

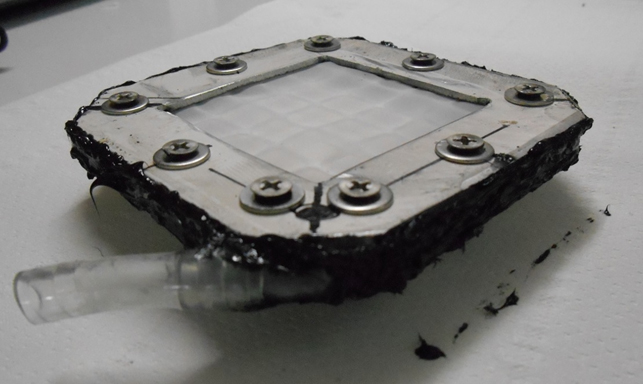

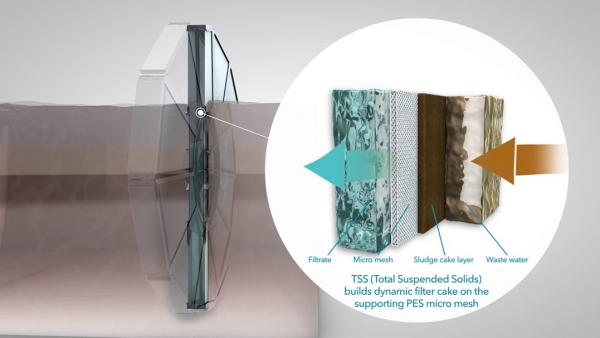

The aim of the study was to evaluate the influence of the mesh pore size on Dynamic Membrane (DM) performance under different solid retention times (SRT). For this purpose, the study compares the results obtained in four long-term tests performed with bench-scale systems equipped with nylon meshes for the treatment of real urban wastewater. Meshes with pore size values of 20 and 50 µm were tested for 15 day SRTs s and compared with and meshes with 50 and 100 µm pore sizes 50 day SRTs. The tests were carried out under the same operating conditions, including temperature, air scouring, hydraulic retention time (HRT), volumetric loading rate (VLR) and flux.

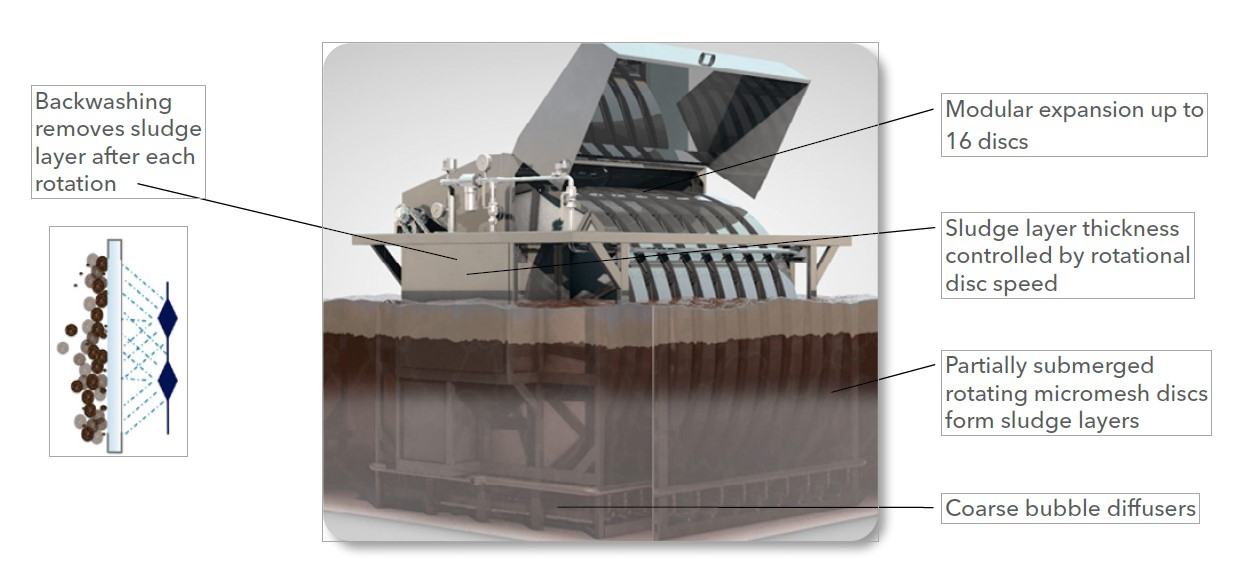

The outcome of the study shows that a rapid formation and a good stability of the DM are generally obtained as a result of steady biological and physical operating conditions. In this regard, high SRTs play a primary role. On the other hand, when this stability cannot be ensured (e.g., under short SRT and/or variable feed conditions), a relatively small pore size of the supporting medium (20 µm or close to it) can favour DM development. For full scale applications, the high variability of the operating conditions can play an important role in the system performance. In particular, feeding, temperature and DO concentrations affect the sludge characteristics and, consequently, all the findings related to this technology need to be tested and validated under variable operating conditions. On the other hand, the automation of the cleaning systems can be easier in large-scale plants, thereby limiting the possible reduction in productivity and the consequent system instability correlated to the operation with a partially clogged filtering support. These issues will be further examined during the piloting of the SFD-MBR in Kanpur, India.

Download the complete article here

More information about the piloted technology can be found here.