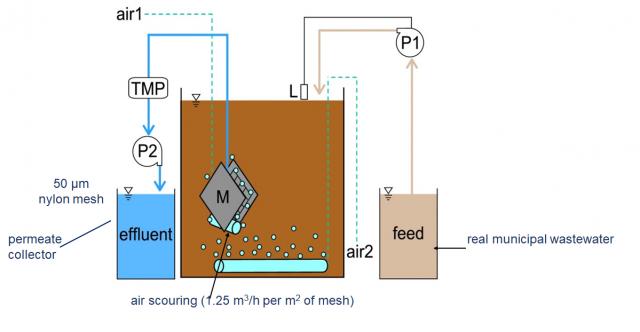

The Self Forming Dynamic Membrane BioReacto (SFD-MBR) is an improvement of an ultrafiltration-based MBR where solid liquid separation is done through a self-forming cake layer that develops on a carrying surface.

The idea is to adopt the same scheme of out-in submerged MBR and replace the filtering membranes with materials having pore sizes larger by two or three orders of magnitude (i.e. 50-100 μm instead of the usual 0.5-0.05 μm of commercial UF-MBR). The main advantages of this technology are the robustness, resilience and cost-effectiveness of the filtering materials when compared to ultrafiltration membranes.

The process itself is run under very limited pressure gaps (normally below 50 mbar), therefore it is suitable for gravity operation, which reduces the energy needs substantially. Bench scale tests performed at CNR-IRSA (Italy) revealed the capability of this technology to produce effluents having similar quality of that normally observed in MBR permeate, except for the microbial indicators that can be easily abated through post-disinfection (low turbidity below 5 NTU allows for the adoption of UV disinfection).

Optimization of the operating conditions with a pilot scale prototype will be done at the Jajmau STP, Kanpur to assess the potential of this technology under real conditions and compare it with a conventional MBR.

Working principles

- A low-cost microfiltration material to produce effluent suitable for irrigation.

- The possibility of using the 'cake' (sludge layer) as a filtration medium.

- Filtration fluxes are much higher than in conventional MBR.

-

Effluent disinfection is required to comply with water reuse standards.

-

Filtration under very low pressure (below 100 mbar) allows for gravity-driven operation.

-

Suitable for decentralized and remote applications (possibly solar-powered).

-

Automated membrane maintenance (self-cleaning) allows for limited man power requirements.

Test results and evaluation

Wastewater treatment and reuse

Lab-scale experiments were conducted to assess process performance in terms of effluent quality and operation sustainability. The results demonstrated excellent COD removal and effluents with low TSS levels and turbidity values suitable for UV-based disinfection and drip irrigation. Moreover, the technology enabled complete nitrification and maintained phosphorus levels. Furthermore, the results of process optimization tests indicated that mesh size and air scouring intensity play crucial roles in maintaining high effluent quality while minimizing manual cleaning requirements. Additionally, high SRT values were shown to improve the system's performance.

The choice of maintenance strategies, such as periodic backwash and air mass load supply, also affected the sustainability of the operation. Finally, although there were differences in configurations between the bench-scale SFD MBR and the pilot plant (Xylem Taron®), comparable results were obtained in terms of effluent quality.

Key findings indicated that higher suspended biomass concentrations and intermittent maintenance of filtering surfaces could offer advantages in terms of bioprocess

stability, energy efficiency, and effluent quality maintenance. Further investigation is planned for optimizing the dynamic membrane maintenance through temporized air mass load and evaluate the effectiveness of this operating strategy with different mesh size supports. Once optimized, this approach can be transferred and tested at larger scale installations.

For more details, consult the deliverable report*

Laboratory test reports and fact sheets on water treatment technology and reuse

* The deliverable report is still under review and has not yet been approved by the European Commission. The final approved version will be uploaded as soon as possible.

Resource Recovery

The SFD MBR lab-scale experiments were conducted to showcase the efficacy and resilience of this technology in producing high-quality effluents suitable for irrigation while minimizing energy consumption, particularly in comparison to conventional MBR systems. Complete nitrification of ammonium to nitrate was consistently achieved under fully aerated conditions, with soluble phosphorus largely retained in the effluent, demonstrating efficient nutrient conservation. The key resources recovered from this process were nutrients (nitrate and phosphate), energy savings stemming from reduced pressure filtration requirements, and water suitable for irrigation. While the effluents met irrigation

standards in most aspects, higher E. Coli concentrations were observed due to the limited bacterial removal capacity of the dynamic membranes, which typically grow on 50 µm pore size supports.

However, the system's efficient removal of suspended solids and the low effluent turbidity facilitated UV-based disinfection, well-suited for water reuse with on-demand, chemical-free operation. Once transferred at a larger scale, this technology will have to be tested for actual energy savings with respect to normal MBR, and also for overall resource recovery with respect to conventional activated sludge. Preliminary results from P recovery through acidification of SFD MBR pilot sewage sludge show that up to 50% of the P could be additionally recovered.

However, the chromium concentrations in the acidified sewage sludge are exceeding the limit values as per the Fertilizer Control (Amendment) Order, 2013. Struvite precipitation from the leachate following the Stuttgart process, which chelates heavy metals through citric acid, could result in a promising recovered product for safe agricultural application. Cost-competitiveness of such struvite products needs to be further evaluated given its high energy and material inputs

For more details, consult the Deliverable Report*:

* The deliverable report is still under review and has not yet been approved by the European Commission. The final approved version will be uploaded as soon as possible.