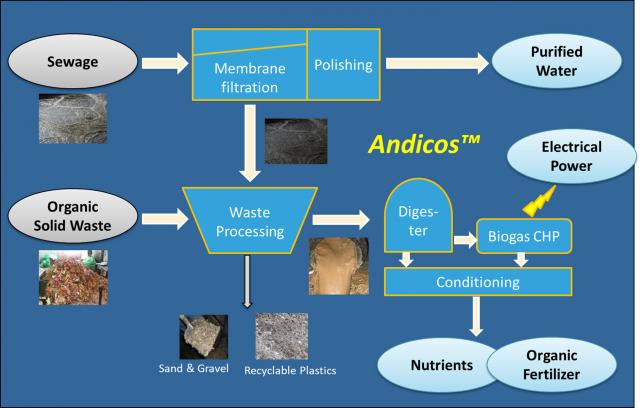

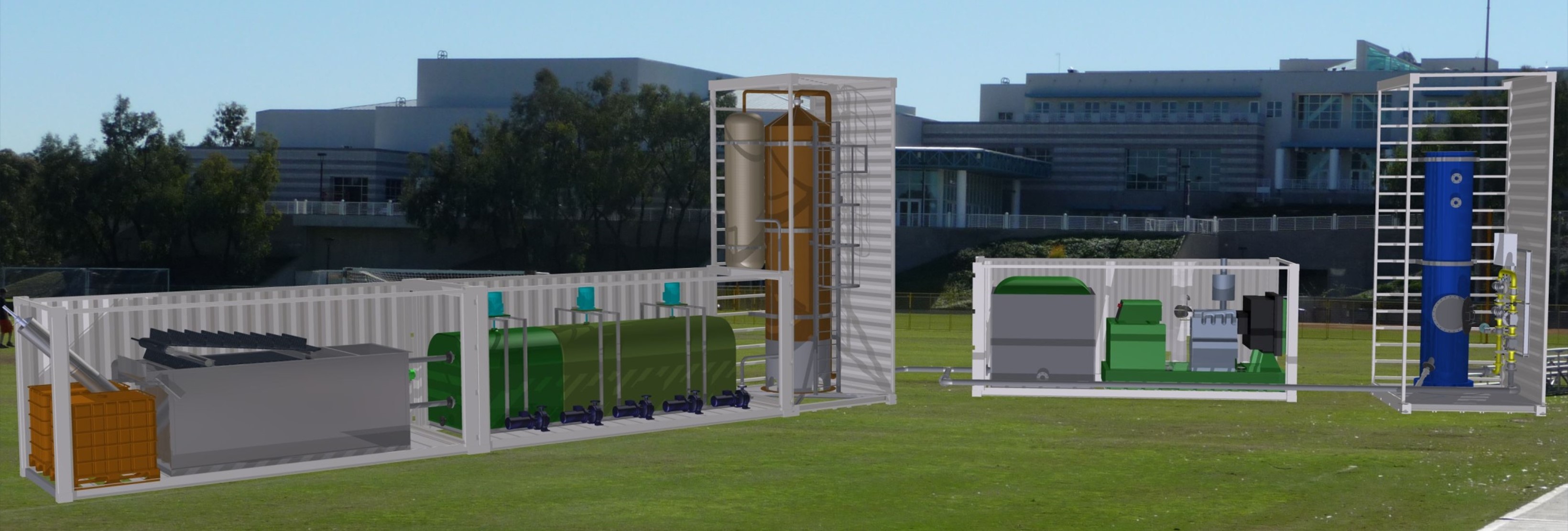

The Andicos™ (Anaerobic Digestion by Combining Organic Waste and Sewage) technology is a modular treatment step that can be added to existing treatment plants. Andicos™ consists of two main steps: filtration through membranes and membrane concentrate processing through a digester with biogas and organic fertilizer production.

The full Andicos™ concept, including both systems, has only been demonstrated at lab scale (TRL 4). In PAVITRA GANGA the full Andicos™ is taken to TRL 6/7.

The Andicos™ technology was selected in this project because of the robust functioning and the modular concept that allows it to be easily added to existing installations. The specific construction of IPC™ membranes allows for rigorous backwashing, up to 2 bar(g) of the membrane. These membranes use 50% less energy and are more compact than other commercially available flat sheet membranes. The ability to regularly backwash membranes makes the process more stable under challenging conditions.

The membrane concentrate is combined with processed organic household waste (pre-treated and fractionated to remove metal, glass, wood, plastics, paper etc..) to increase organic matter content to levels that allow efficient anaerobic digester functioning.

The digester produces biogas and a nutrient-rich digestate that can be used as a fertilizer, thus upcycling organic waste and wastewater and decreasing the net costs of treatment. The resulting effluent from the IPC™ membranes is less polluted compared to current effluent, and is safer and more sustainable for water re-use (irrigation) and improving the river water quality.

Main goals

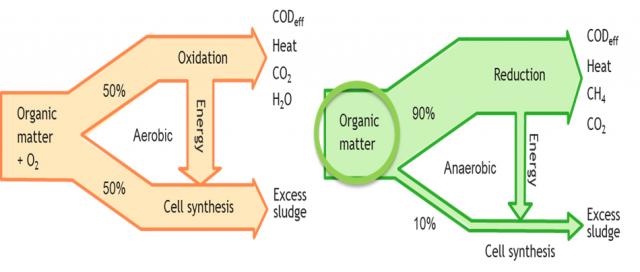

- From energy consuming towards energy producing concepts and technologies

- Aerobic: - 0,75 to 1,5 kWh/kg COD removed vs. Anaerobic: + 3 kWh/kg COD removed

- AndicosTM deals with challenges in liquid sewage and solid (organic) waste streams

- Interesting for Indian setting due to higher temperatures and existing needs in sewage and waste treatments

- Possibility to integrate AndicosTM into existing aerobic WWT plants (to reduce overload, high energy consumption, high sludge production…)

Test results and evaluation

Wastewater treatment and reuse

Lab-scale experiments were conducted at IIT Kanpur using BFM membranes to filter Indian wastewater, including wastewater from IIT Kanpur Campus and more challenging sewage from the Jajmau Standard Treatment Plant (STP), contaminated with tannery discharges.

Critical flux experiments with the primary settled sewage showed an optimal filtration flux range of 15 – 25 L/h-m2. The permeate flow was around 95% of the wastewater flow with a COD concentration <120 mg/L. The concentrated wastewater represented around 5% of the initial wastewater flow with a COD concentration of 9 500 mg/L and a TSS concentration of 9 000 mg/L. The COD loss due to biodegradation in the air-scoured membrane tank was 32%.

The change in the sewage characteristics observed after COVID-19 (2021-2022) had a major impact on both the composition of the concentrate stream and the unwished biodegradation that took place in the

membrane reactor. Up to 70% of the COD was lost because of biodegradation indicating only limited concentration of the e to the deposition of biofilm on reactor walls. To optimize the membrane cleaning process and frequency, different concentrations of sodium hypochlorite were tested using 100 - 900 ppm active chlorine solutions.

The laboratory tests have been invaluable to assess different options to reduce biodegradation losses, which would be more costly to undertake at pilot scale. With the drastic improvements of the Jajmau STP influent occurring the during the project, further laboratory scale work is investigating the treatment of different mixes of CETP and STP influent.

For more details, consult the deliverable report*: Laboratory test reports and fact sheets on water treatment technology and reuse'.

* The deliverable report is still under review and has not yet been approved by the European Commission. The final approved version will be uploaded as soon as possible.

Resource Recovery

Andicos uses anaerobic digestion of organic waste and/or wastewater under an increased organic loading rate. The increase in organic load can be obtained by filtering the wastewater to concentrate it up to 20 times with a Blue Foot Membranes (IPC membranes) filtration process.

A 40 L anaerobic digester at IIT Kanpur was employed for anaerobic digestion of primary sludge (PS) sourced from the primary settling tank of STP Jajmau. PS, rich in lipids, fatty acids, and fibre, displayed substantial potential for methane production compared to secondary sludge due to its enhanced biodegradability.

The digester initially operated with a 40-day hydraulic retention time (HRT) for 300 days and was later reduced to 30 days.

Biogas production commenced after 300 days of inoculation, with an average daily production of 6 L from day 320 to 360, which subsequently decreased to 2 L per day by day 400. During this period, there was an approximate 20% reduction in total chemical oxygen demand (COD), and volatile fatty acids (VFA) concentration in the digester ranged from 100 to 110 mg/L as CaCO3. The volatile solids (VS) to total solids (TS) ratio fluctuated between 0.25 and 0.28; however, it decreased to 0.15 after day 400, leading to a decline in biogas production.

The system's pH remained within the range of 7.2 to 7.4 throughout operation, and the total methanogenic activity at the end of 400 days was determined to be 18.1 ml methane per gram of volatile solids per day.

With the drastic improvements of STP influent occurring the during the project, further laboratory scale work is investigating the treatment of different mixes of CETP and STP influent, as these may show opportunities to increase biogas production.

During the project it was agreed to put less emphasis on mixing food wastes with sewage concentrates, so as to avoid mixing fecal and non-fecal waste streams, but further work could be done on combing septic tank waste streams with sewage waste streams to increase biogas production, because septic tanks waste collection and disposal remains an important activity in urban areas of India.

For more details, consult the Deliverable Report*:

* The deliverable report is still under review and has not yet been approved by the European Commission. The final approved version will be uploaded as soon as possible.